- Warehouse Management System

Let the system, not manual effort run your warehouse

Wasted time on stock sheets, mixed-up orders, and information gaps belong in the past. With Inlab’s Warehouse Management System (WMS), monitor warehouse operations in real time, use automated controls to minimise errors, and add pinpoint accuracy to every order.

Accuracy in Stock

Fast Order Fulfilment

Minimal Errors

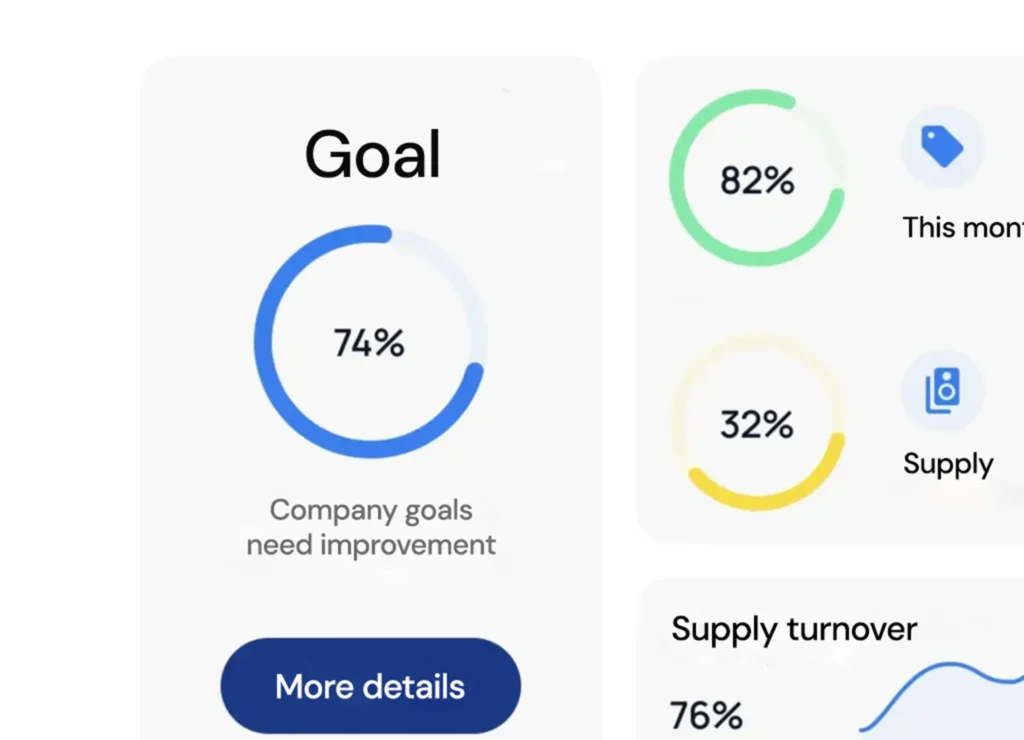

Precise Performance

- Why?

Move from Oversight to True Management of Warehouse Operations

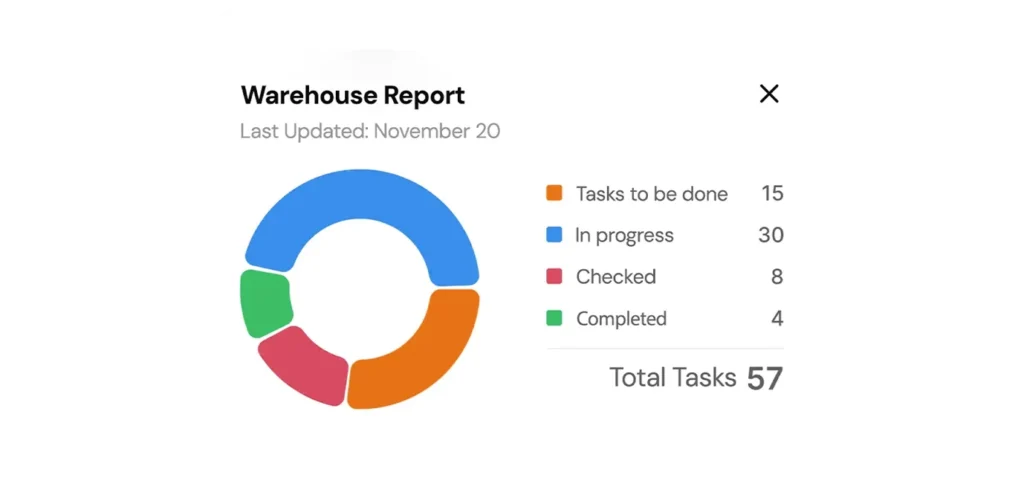

With the WMS Warehouse Management System, you see exactly what is happening in the warehouse at any moment, automate end-to-end processes, and trace every item’s journey through the system. Our goal is fewer errors, higher speed, and complete visibility.

Live Inventory View

Instantly see where each product is located, when it arrived, and how much remains in stock.

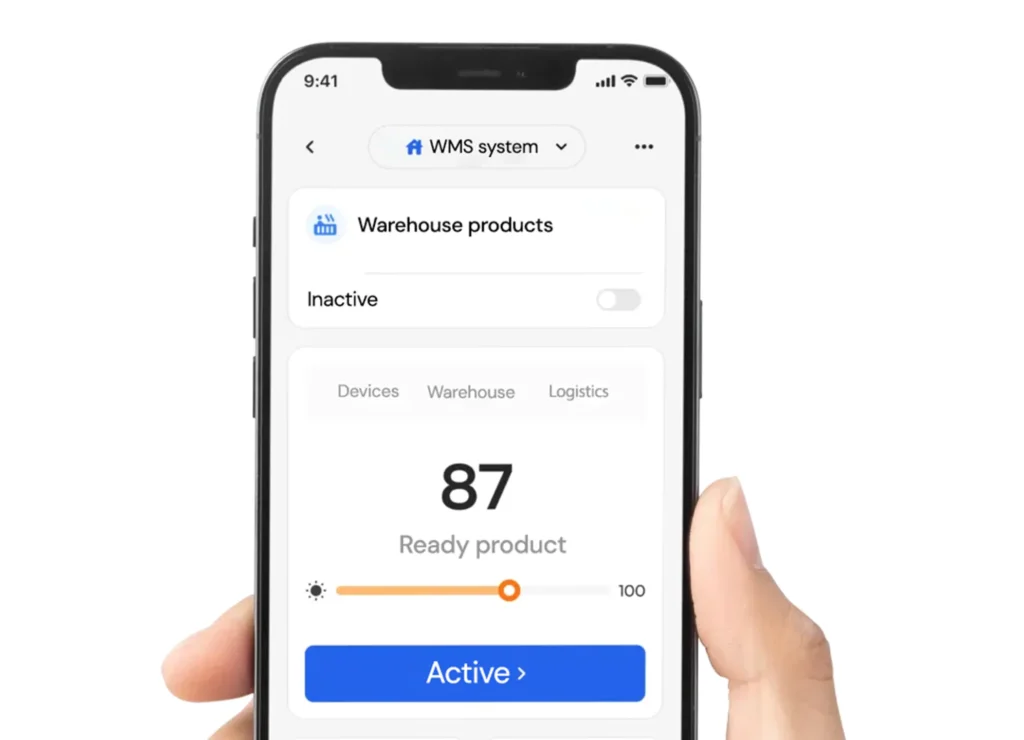

Mobile Compatibility

Equip staff with handheld devices so they can scan items and work faster and more accurately inside the warehouse.

End-to-End Order Tracking

Follow every stage from inbound receipt to outbound shipment, right through to the customer.

Slotting and Replenishment Optimisation

The system automatically places products in ideal locations and plans replenishment cycles.

No More Late Orders or Mixed-Up Stock

Automate warehouse operations, maintain real-time control, and execute every delivery correctly with Inlab’s WMS. Your warehouse now runs on a system, not on paper.

- FAQs

Frequently Asked Questions

No. The WMS is suitable for both small and high-volume warehouses. Thanks to its flexible modules, it can be deployed in any structure.

We implement the WMS in phases. Current operations continue without interruption while the system is configured and tested in the background.

Yes. Oracle WMS can be aligned with other systems. During integration we take your current software into account and merge data flows securely, eliminating information gaps between platforms.

Absolutely. The Inlab team provides both in-person and online training, preparing your employees for WMS usage step by step.

Stock accuracy increases, human errors decrease, the picking process accelerates, and orders are fulfilled more correctly. This boosts both customer satisfaction and internal productivity.